Learning from losses

ArticleDecember 8, 2022

The European economies and labor market are undergoing an unprecedented digital transformation that has accelerated the rise of diverse (non-standard, new) forms of work. With it comes bodily injuries, but there are things to be learned from this. Below our Nordic Liability team shares their knowledge.

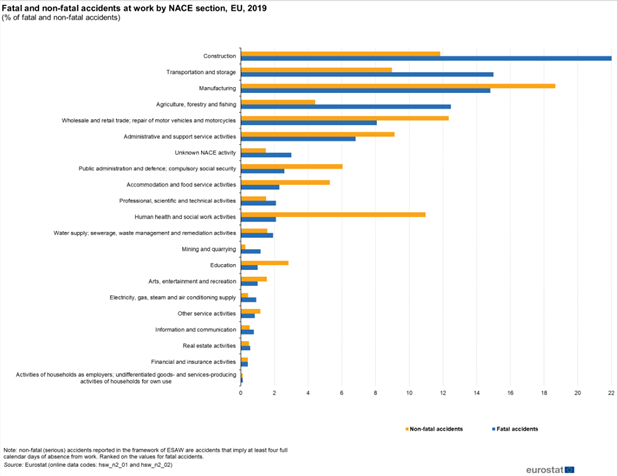

Ref: Accidents at work statistics - Statistics Explained (europa.eu).

Fatal_and_non-fatal_accidents_5.png (2588×2023) (europa.eu)

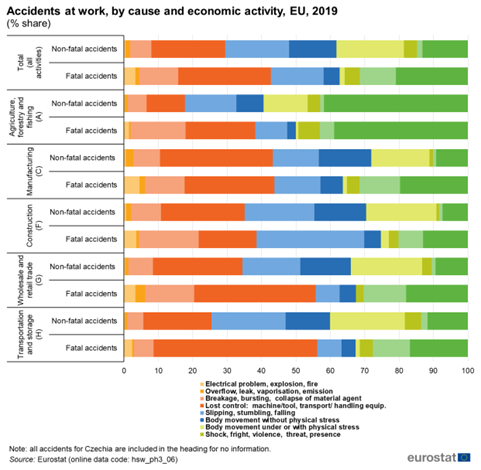

Ref: Accidents at work - statistics on causes and circumstances - Statistics Explained (europa.eu)

Accidents_at_work,_by_cause_and_economic_activity,_EU,_2019_(%_share).png (1483×1453) (europa.eu)

This correlates with statistics from the US showing that transportation incidents clearly are the major reason for fatal occupational injuries. Falls, slips and trips, contact with objects and equipment, violence and other injuries by persons or animals and exposure to harmful substances or environments has almost equal contribution. Ref: Most Dangerous Industries - Injury Facts (nsc.org) Ref. Fatal occupational injuries by event (bls.gov)

Learning from losses

Even though the statistics accumulate all type of accidents at work (not only the ones caused by a product), it is still well worth to take them into consideration when assessing the risk of a product for professional use that could potentially cause bodily injury to a worker. Not surprisingly, loss statics for bodily injury to workers by products for professional use produced by Nordic corporations shows similarities to the statistics from the US and EU.

Preventive actions

From occurred losses within Zurich portfolio some preventive measures can be learned for product manufacturers:

- Importance of product warnings and instructions being available, clearly visible at the time of need, durable, complete, clear, and effective need to be emphasized. Proper product information is a legal duty of care of a manufacturer and serves as an important preventive character. The instructions and warnings will be studied and analysed in dept after a loss.

Having a multi-functional team including design engineers and legal advisor/department in the development and review of warnings and instructions is recommended. Especially for an injury occurring in USA the liability and compliance of the producer is often part of the loss investigation and/or legal proceedings even though it is obvious that the user did not follow instructions, standard operating procedures or behaved in a careless way.

- Importance of designing products in accordance with the state of science and technology and equally safe as competitors, otherwise liability can be claimed for not designing a product as safe as reasonably possible. Safe product design belongs to the “legal duties of care of a manufacturer in design”.

- Importance of taking all usage situation into consideration during design of product, assembly and installation of safety guards, etc. Intended use, foreseeable misuse as well as putting into operation, maintenance, cleaning, repair and product disposal modes need to be taken into consideration.

- To be able to demonstrate the care that has been taken in design, manufacturing and sell safe products an effective documentation and document control system is important. Documentation showing safeguards in place at the time of delivery has shown to be an important defence in post-loss investigation. Documents pertinent to product liability loss control should be retained for at least the expected life of the product plus the longest statute of limitation.

- When servicing a machine at the location of a customer, it is important to have the scope of the service/work and the execution of the work clearly documented and defined together with the customer. If not clearly defined the service provider could be claimed liable for not verifying how a machine upgrade or modification affect the safety of the standard operating procedures in place. Service providers at site prior to an accident have been questioned for not giving a warning of unsafe conditions at a machine or workstation not part of the scope of service. Companies have also been questioned for not following up warning letters sent prior to an accident for a safety violation observed at site.

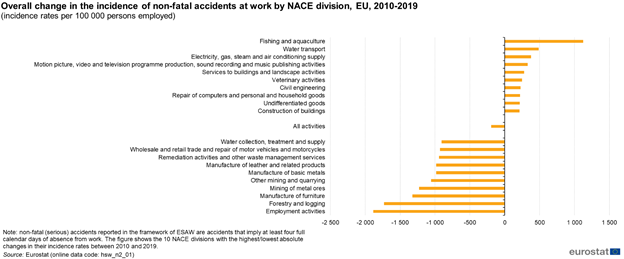

Development over time

Back to the European statistics, data shows that industrial activities (manufacturing, mining, etc) accounted for many of the biggest reductions in incident rates between 2010-2019. Increased focus on occupational safety is certainly a high contributing factor to the lower frequency of accidents, however, an increased level of automatization resulting in fewer individuals present in dangerous environments, is certainly also contributing to the reduction of injuries.

Similar to the discussion about shift of liability from the driver to the producer for autonomous vehicles, where the responsibility to not run into something or someone when parking with the help of self-parking feature will shift from the driver to the engineer developing and programming the functionality. The same shift of liability from the user to the producer can be seen for trucks, mobile and stationary platforms, production lines etc. equipped with warning systems and programmed to automatically stop if a dangerous situation materializes. The situation is however even more complex when taking into consideration the responsibility of the employer to offer and ensure a safe work environment. How the liability and indemnity will be considered and distributed is however highly dependent on jurisdictions.